About Bassline Creations AU

Bassline Creations AU stands at the forefront of custom camera equipment manufacturing in Australia. Nestled in the vibrant city of Sydney, our workshop is a hub of innovation where design ingenuity meets meticulous engineering. For over a decade, we've been passionately crafting bespoke camera solutions for a diverse clientele, ranging from independent filmmakers capturing the raw beauty of the outback to high-end photographers documenting the delicate details of studio portraits. Our journey began with a simple yet profound mission: to bridge the gap between standard, off-the-shelf equipment and the unique, often complex, demands of visual storytellers.

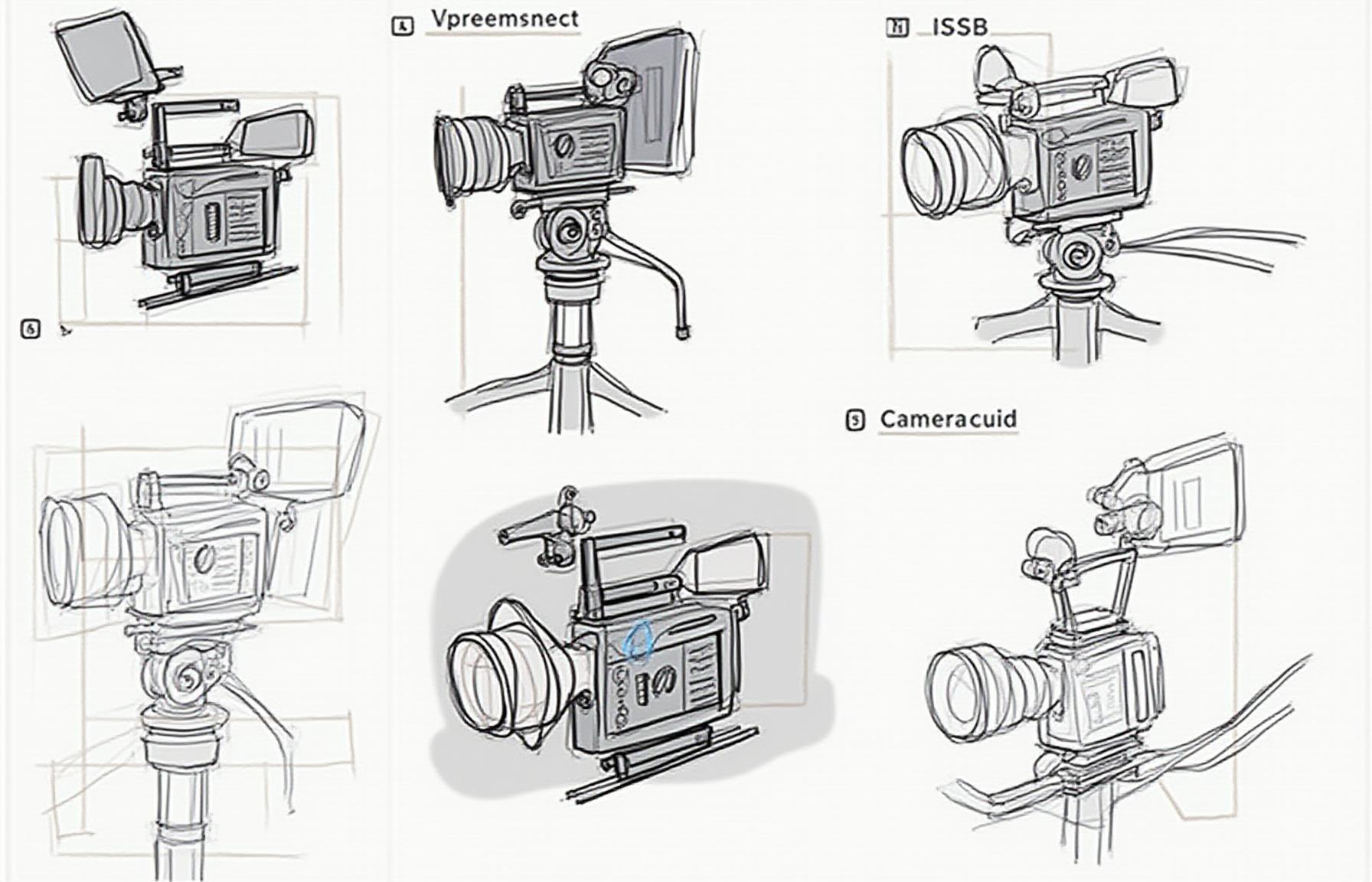

From our humble beginnings in a small garage, fueled by a love for cinematography and a knack for engineering, we've grown into a respected name in the industry. Our values are deeply rooted in precision, innovation, and education. We believe in pushing the boundaries of what's possible with camera technology, constantly exploring new materials, techniques, and designs. Our commitment extends beyond just manufacturing; we are dedicated to empowering the next generation of camera professionals through knowledge sharing and skill development. We see our educational initiative as a vital part of our mission, aiming to demystify the intricate world of camera equipment and make advanced knowledge accessible to enthusiasts and professionals alike.

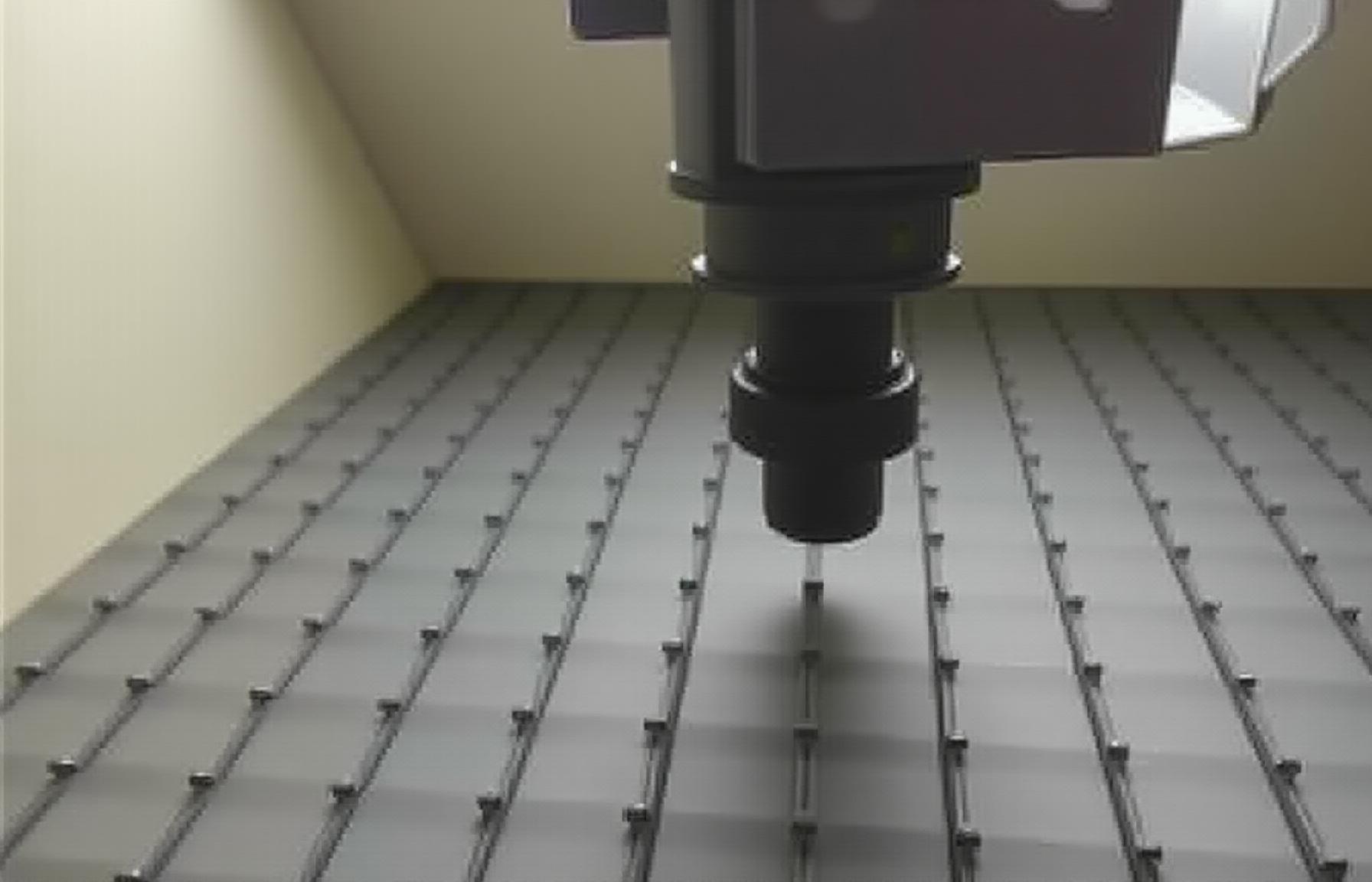

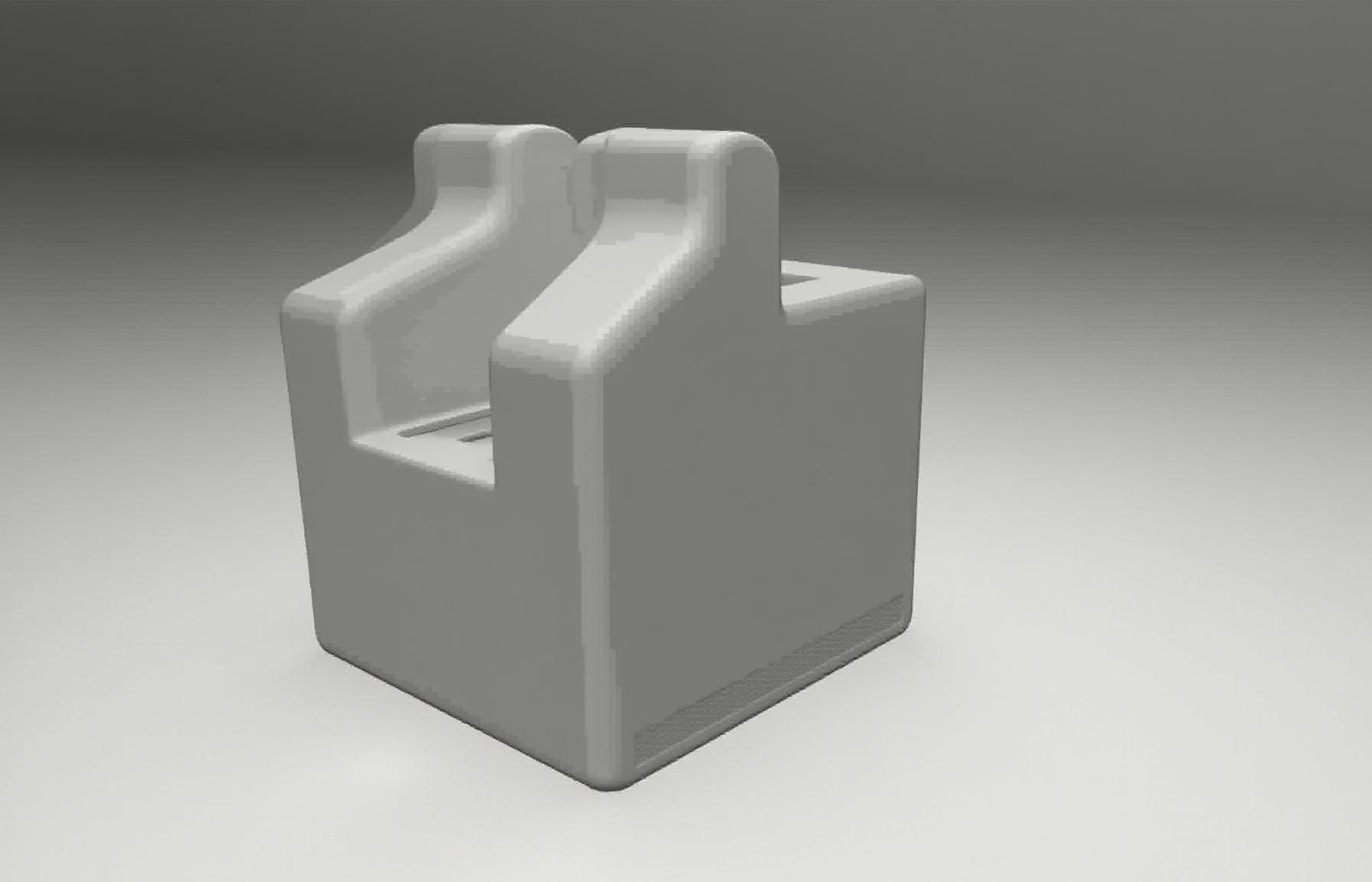

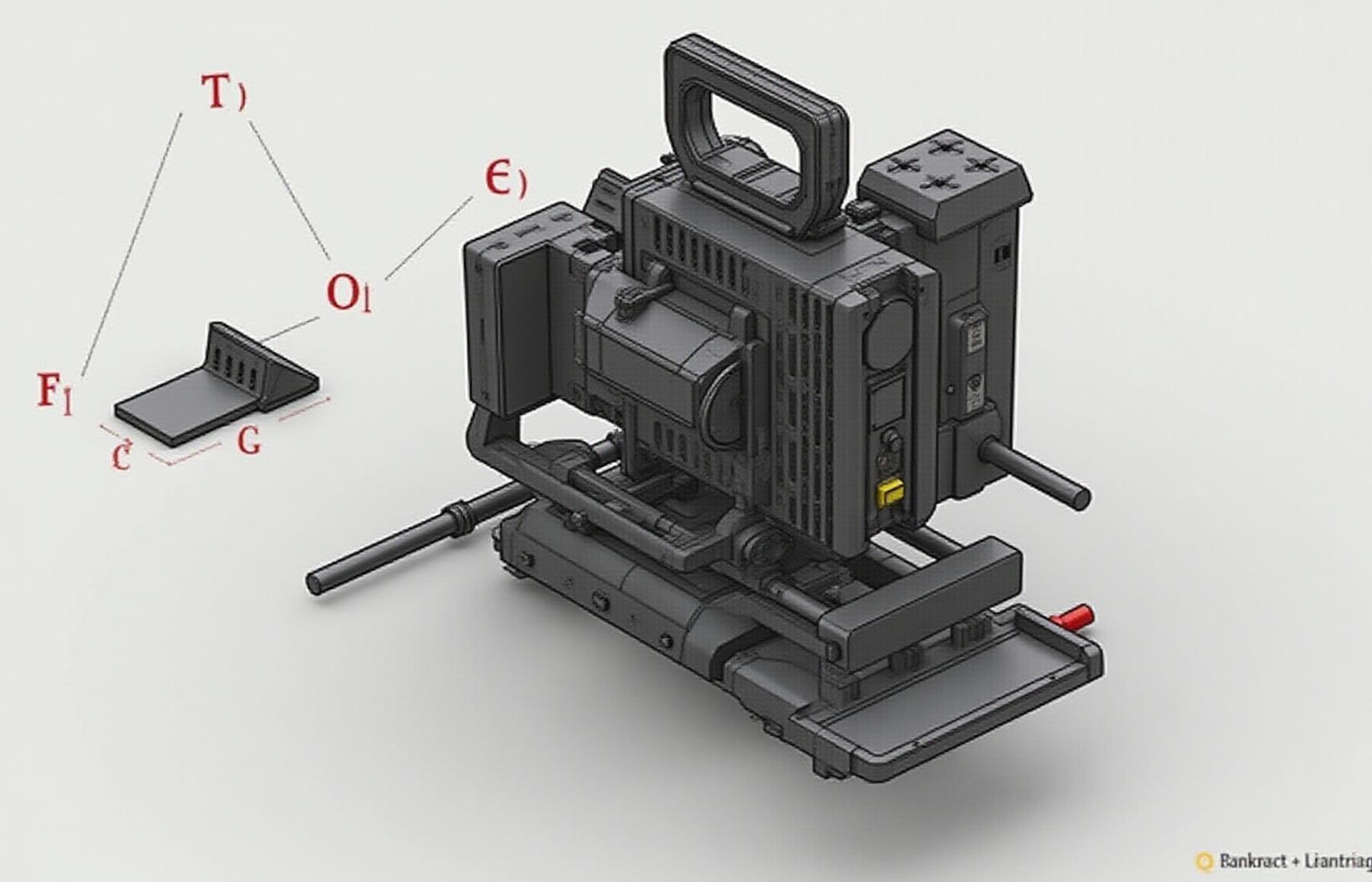

At Bassline Creations AU, we are more than just manufacturers; we are educators, innovators, and passionate advocates for the art and science of camera technology. We pride ourselves on our collaborative approach, working closely with our clients to understand their specific needs and challenges, ensuring that every piece of equipment we create is not just functional, but perfectly tailored to their creative vision. Our workshop is equipped with state-of-the-art machinery, including advanced CNC milling machines and 3D printers, allowing us to handle projects of any scale and complexity with unwavering precision. We source only the highest quality materials, ensuring durability and performance in every product that leaves our Sydney facility. We are deeply committed to sustainability and ethical practices, striving to minimize our environmental footprint and contribute positively to our community. Join us as we continue to explore the fascinating intersection of technology and visual storytelling, right here from the heart of Sydney, Australia.

Expert Craftsmanship

Learn from our experienced team of engineers and technicians who are dedicated to the art of custom camera equipment manufacturing. Our team's expertise is the cornerstone of our educational resources.

Innovative Solutions

Discover the cutting-edge techniques and technologies we employ in designing and fabricating advanced camera rigs and components. Our resources highlight these innovations.

Industry Insights

Gain valuable insights into the camera equipment industry through our educational content, workshops, and resources. We share our knowledge to empower you.